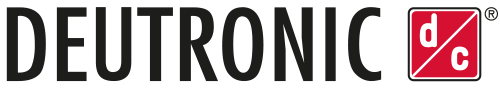

PCB development, design and data check

Deutronic offers the complete support in the field of electronics development. From the concept of your ideas to the finished serial product. PCB new concept, redesign, circuit board layout, series optimization and definition / modification of components are our services we develop together with and for our customers.

- New development

- Redesign

- Data check

- Production optimization

Purchase management

Buying PCB components is an important process for finalizing your PCB design projects. Here Deutronic acts globally to ensure a functioning delivery chain. Components with corresponding specifications such as forecasts about life cycle, alternatives. Authorized distributors, environment data, export control data, research service are in our scope of responsibility. Together with worldwide supplier contacts our supply managements meets no limits. In more and more hectic times market risks can occur which require an obsolescence management process. Our obsolescence management is the safest way for a long-term warranty of your product life cycle and avoids purchasing high quantities for your storage.

- Worldwide material purchase

- Component database

- Active and passive components, mechanics and accessories

- Consignation storage

- Many years of supplier relation

- Contact to customers can be provided

- Phasing out information

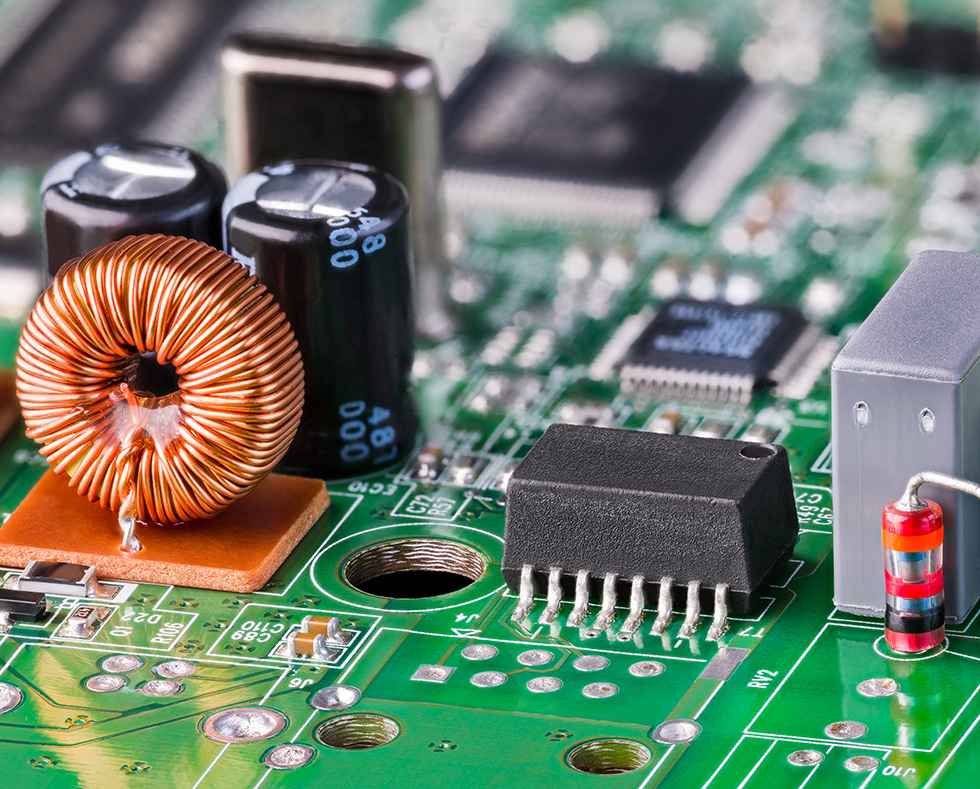

SMD Prototyping

Deutronic is your competent partner for producing a development sample. Prototypes and small series up to 1 piece. We can realize the cycle of a prototype from PCB design, production and optimization in shortest time in series quality. We want a quick success for our customers and thus a short „time-2-market“.

Component range

- Chip from 01005

- Melf from 0102

- All SO, SOT, PLCC

- QFP up to 200 x 110 mm and pitch 0,25 mm

- Plug connectors

- BGA

- Flip-Chip components

- Tests and packing

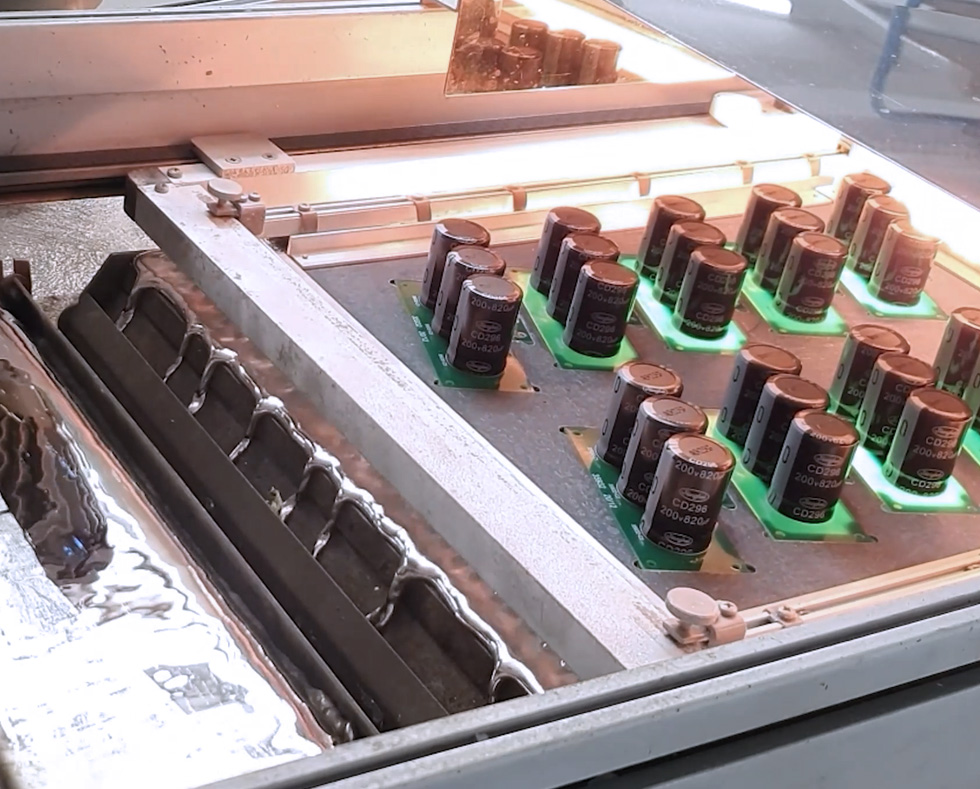

SMD filling into machine

Our machines include 3 Siplance SMD filling in machines and the corresponding steaming phases. Thus completing circuit boards with components mouted onto the surface – such as resitors, micro controllers and condensators are no problem for us.

It enables us to cover the whole range of components flexibly and process also bigger orders quickly and uncomplicated.

Range of components in SMD process:

- Chip from 01005

- Melf from 0102

- All SO, SOT, PLCC

- QFP up to 55 x 55 mm and pitch 0,4 mm

- Plug connectors

- BGA

- Flip-Chip components

- Sample building

- Prototypes

- Small, medium and big series

- Tests and packing

THT manual assembly

Manual assembly with special components for sample building, prototypes and small series is one of the core competencies of Deutronic. With our wave soldering machine standardized soldering is also possible for these components – manually assembled. It ensures a regular and constant heating and a constant soldering result. 100 percent visual inspection and further sensoric and electric checking stations and component tests are integrated into our zero mistake strategy

- Individual manual assembly

- Dispenser machines

- Musterbau

- Sample building

- Small series

- Tests and packing

Soldering techniques

The SMD soldering technique requires innovative tools to connect with absolute precision minimized SMD components. With our steam phase soldering technique we can realize components lead-free for highly-sensitive applications. By selective soldering, wave soldering or with our modern reflow soldering system – together with our integrated quality control our zero mistake strategy is continued.

- Production class IPC 1 / 2

- Wired components – lead-free

- Wave soldering

- Selective soldering

- Steam phase soldering

- Individual manual soldering

Grouting, printing

Electronic components, assembly groups and devices have to work in changing surrounding conditions perfectly for years – for the smooth functioning of electronics. Disturbing elements such as vibrations – eg in the car industry – and also electrical faults have a negative impact on the reliable functioning of electronics.

- Grouting with reaction resin

- Screen printing, pad printing

Quality management / testing technology

Our “zero mistake“ strategy is the most important message from Deutronic to its customers. Besides runnings investments into most modern testing techniques staff traininig on a regular basis and audits are part of our quality promise. Our quality management system includes evaluation and testing of our suppliers, checking of contracts before orders are confirmed; material check, permanent controls in running production and function tests; final control and committed customer service.

- Incoming goods inspection

- 100% visual inspection

- Automatic optical inspection (AOi)

- Automated flashing

- Automated taking into operation and function test

- Burn-in-test (climate and stress test)

Quality and warranty

For everything we do quality up to the smallest detail is in the foreground. Thus we make sure that our customers are more than happy. Avoiding mistakes and eliminating them is the basis of our quality policy with the aim: Zero mistakes! In all areas of our development up to the After Sales Service.

Together with our warranties according to customer-specific quality standards we ensure a good cooperation in all the years.

Quality systems according to:

- DIN EN ISO 9001

- DIN EN ISO 14001

- DIN EN ISO 13485

- Visual inspection, AOI

- Electric test

- Special tests according to customer

- Warranty of customer-specific quality standards