Research and development

New and technically advanced products of mechanics and electronics are in most cases the perfect combination from a good idea, curious creation and experience in many fields and practical know-how. Our development and design teams both have a solid technical background and extensive practical experience. The core competences at Deutronic are the development of individual soft- and hardware in order to realize customer demands in a creative way in practice. For us every project is a thrilling challenge in the world of technology and techniques from today and tomorrow.

Contact us – we will be happy to help you.

- Specification and concepts

- Customer-related algorythms and software development

- Mechanical CAD design

- Production and function simulation

- Driving and control technology

- Electric and electronics project work

- Risk analysis and evaluation

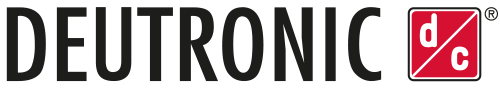

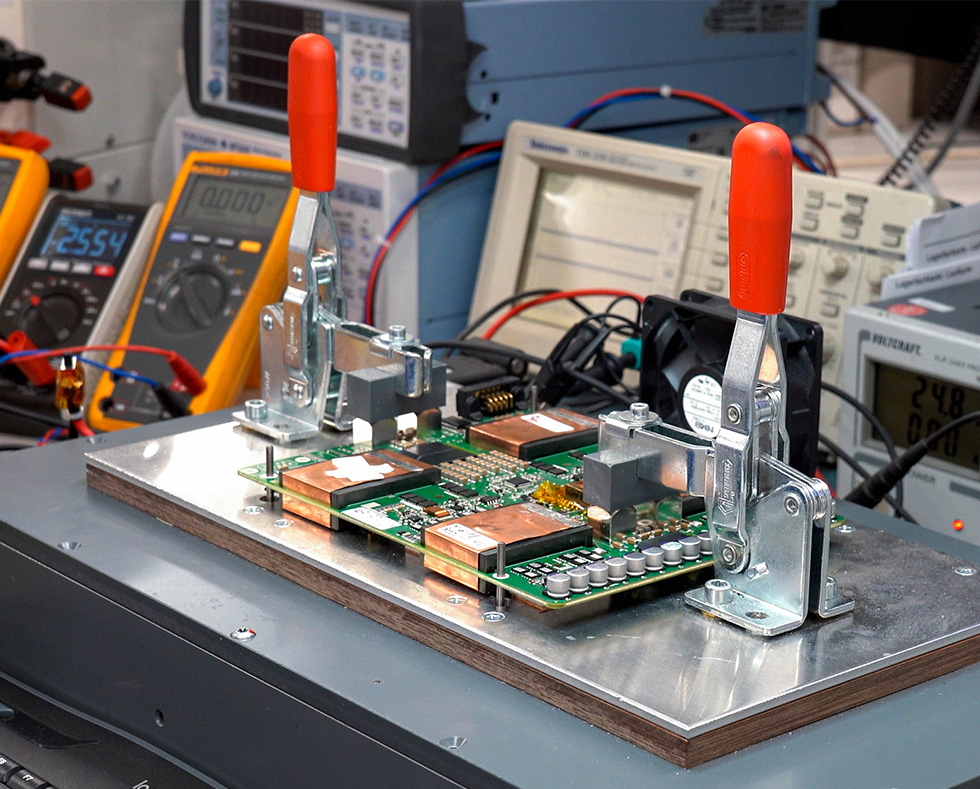

Prototyping

We produce prototypes from serial processes and production with a maturity model. We use the experienced values from testing the components in an every day surrounding for further processing. Our prototypes are not only pure models, but designed for practice. Thus we win precious information with regards to functionality and durability. In this way we launch your drafts and small series to the market.

- Validation and test of prototypes with first sample testing report

- Quick production directly wiith delivered, digital 3D data

- Cost saving by production without tools

- Cost saving by optimizing processes (DTC)

- Minimizing of risks by risk management

- Project-related material choice (delivery chain optimization)

- Documentation

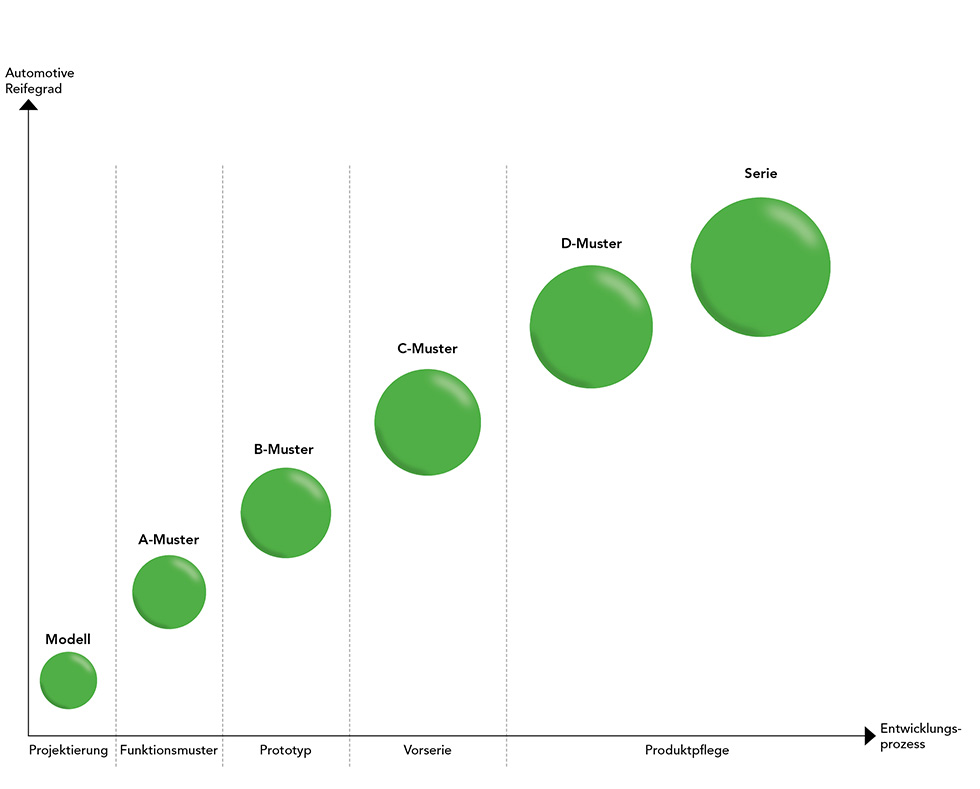

Mechanical production

We process sheet metal with our partner companies with state-of-the-art technologies, such as laser cutting, stamping, nibbling and CNC milling. Manual and automatic degrating is also used as well as slided grinding, CNC bending, deforming, pressing in, different welding procedures (WIG, TIG, MAG, MIG), wet painting, assembly and quality control.

- CNC stamp laser

- Degrating/aligning

- Bending

- Turning/milling

- Pressing

- Welding/grinding

- Roboter welding

- CNC pin welding with tip ignition

- Spot welding

- Corner seam welding

- Manual welding

- Painting

- Screen printing

- Pickling/passivation

- Soldering

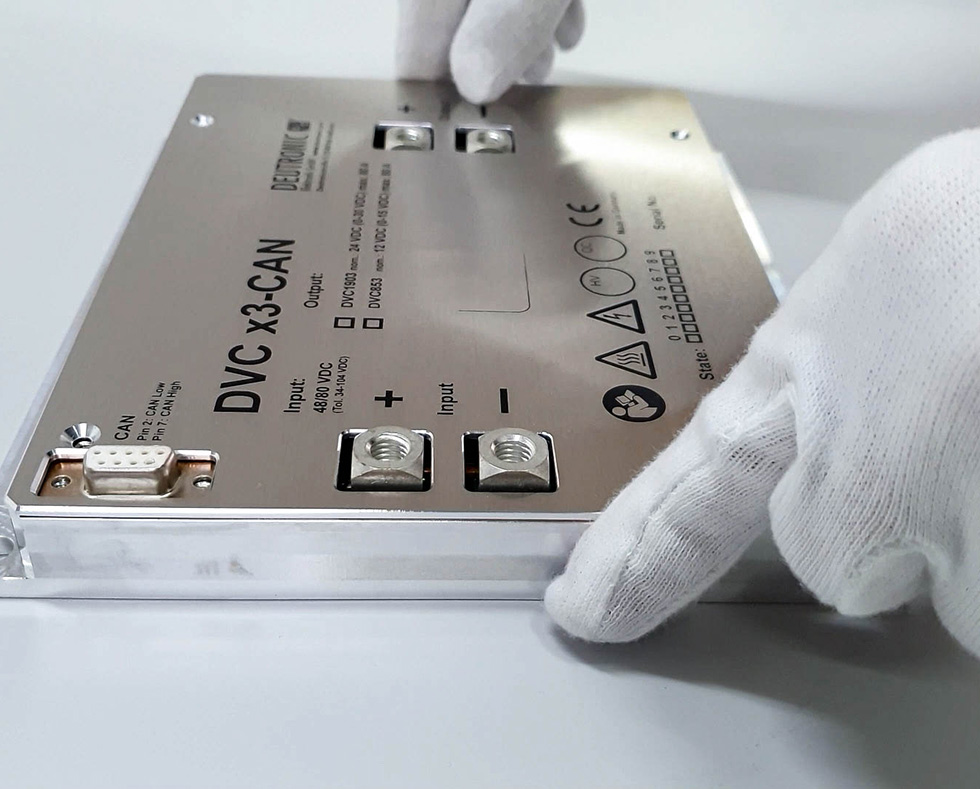

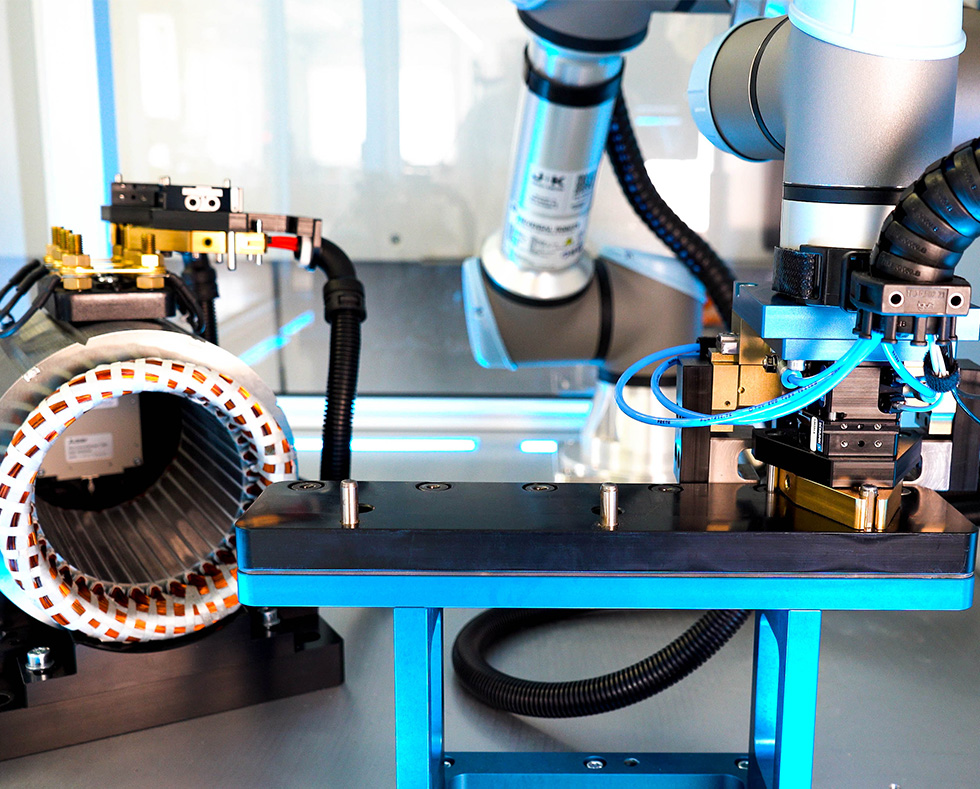

Assembly technology

As supplier of systems of electronic and mechanical components we deliver those according to customer specifications. Many years of experience as service provider in that field are an added value for our customers. Let us work together for a perfect solution for your application.

- Mechanical assembly

- Assembly, resting, shipping in a controlled way

- Electronics and functional tests after customers’ requirements

- Assembly on site

- Taking into operation

Mechanics and mechatronics

Electromechanical components, devices and complex systems are easy to handle due to the deep value chain. Our powerful mechanical production with conventional and CNC machines can meet your specific demands with regards to electromechanical components fast and flexible. In combination with engineering, individual software development and cable assembly we can offer to our customers systems from one hand. We are also in the position to react in maximum flexibility to customer wishes.

- New development

- Redesign

- Design to Cost (DTC)

- Optimized production

Industry electronics/automation

Deutronic has outstanding competence and many years of experience in developing hard- and software. In close cooperation with our customers we elaborate innovative products such as application software.

These are our products and services offered:

- Soft- and hardware from one hand

- Development of individual industry software, firmware

- Intuitive operating fields

- Digital information systems

- Integration of interfaces and control technology

- Field bus, networks

- Remote access

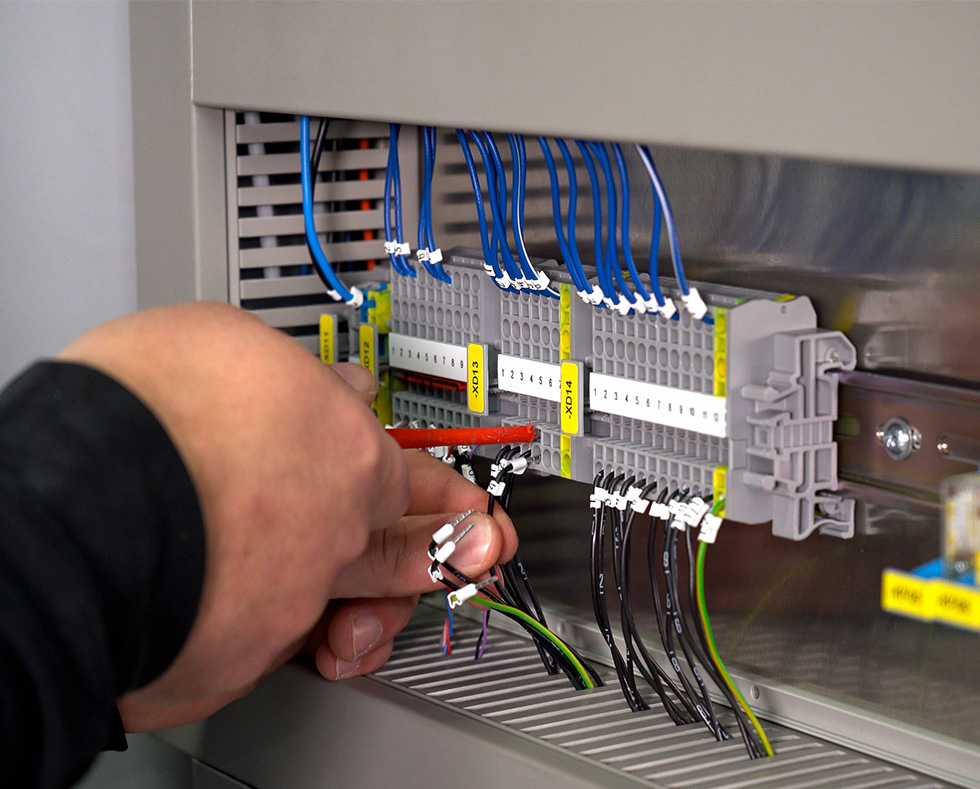

Control cabinet building

Control cabinet building is an electrotechnical service which puts electric and electronical components into a metal housing, structures and connects them. The service starts with development/design and ends with wiring the control cabinet according to the electrotechnical design plan.

Our qualified electrical engineers, electrical technicians and masters and electrical workers provide the set-up and the professional wiring of the control cabinets within the field of automation and control.

- Production of control cabinets, distributors and control panels

- Individual planning with EPLAN CAD software

- Use of specific and tested components

- Sticking to requirements of suppliers

- Tests/measurements

- Standardized documentation

Testing technology

Our testing labs offer extended testing technology for avoiding field and early failures. So we reduce effectively the duration and costs in monitoring the process. If needed, we develop a testing strategy according to your demands and consult you for its implementation.

- Optical inspection

- Active and passive “Burn-In-Test”

- System test – with PC and manual

- Special mechanical and electronic tests according to customer specification

After Sales Service

Our success are happy customers. Thus it is very important to be available for the customer also after successful delivery and taking into operation. We offer tried and tested solutions for maintenance, spare parts, software and redesign or product successors.

- Modification

- Upgrades

- Repair